Services — from sample proofing to serialized production

Artwork preparation & vector optimisation

We convert client artwork into machine-ready files, optimising vector paths for engraving and raster images for tone control. This stage includes kerf compensation for cut processes, path smoothing and nesting strategies for efficient marking.

Material trials & proof samples

Prior to full production we run sample proofs on representative substrates to verify contrast, tolerances and surface effects. Samples are photographed and tagged with process parameters so approved proofs can be reproduced exactly.

Serialized UID & batch marking

We implement serialized marking for part-level identification, including human-readable IDs, barcodes and 2D codes. Data integration options include CSV upload for batch processing or API integration for automated workflows.

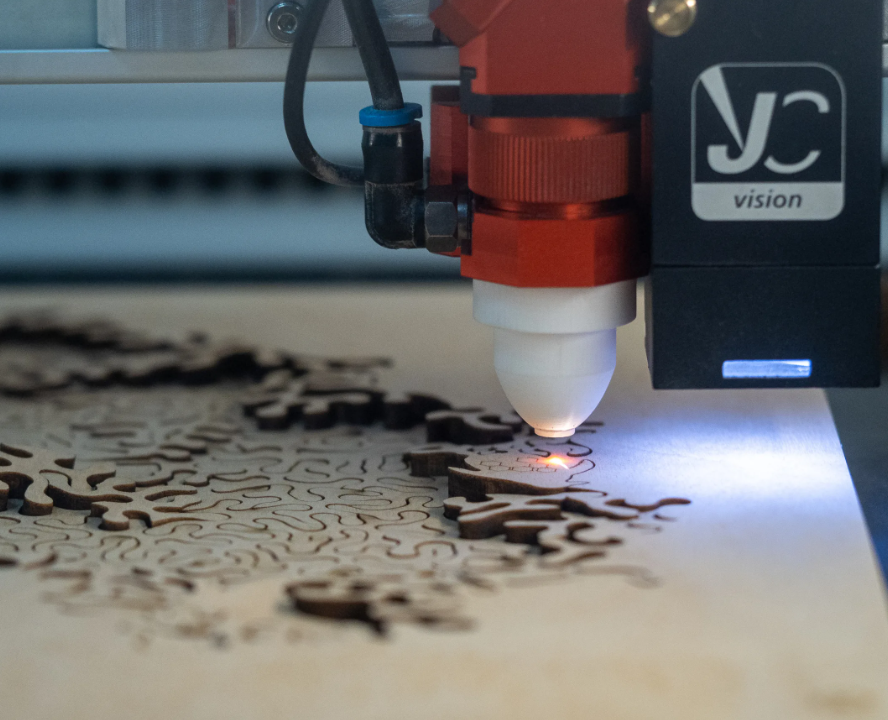

Precision engraving & decorative marking

High-resolution engraving for decorative and tactile results on wood, leather and coated substrates. We adjust raster resolution and scanning strategies to balance speed and tonal smoothness.

Micro-marking & tight-tolerance jobs

For parts requiring very small marks we provide micro-marking capabilities with precise fixturing and high-stability jigs to maintain registration across runs.

Quality assurance & post-process verification

Final QA includes dimensional checks where applicable, photographic record keeping, and optional contrast measurement. We provide batch certificates and process logs on request to support traceability and compliance documentation.

Services image

How to start

1) Send a brief with material, artwork and quantities; 2) receive a sample quote and lead-time; 3) approve a sample proof; 4) schedule the production run. For serialized marking we offer secure data upload options and batch process templates to streamline production.

Turnaround & logistics

Typical sample turnaround is 2–5 business days depending on material and complexity; small runs usually complete within 5–10 business days. Shipping and kitting options are available for finished parts.