Material-specific parameterisation for lasting contrast

Different substrates require tailored laser settings. We develop a material process sheet for each substrate class—specifying pulse duration, power, frequency and scan strategy—to create marks that deliver optimal contrast while avoiding substrate damage. For metals this may mean controlled micro-annealing or controlled oxidation, while for polymers we choose settings to avoid burn-through or structural weakening. Detailed records of chosen parameters are kept to ensure repeatability across future batches.

Traceability solutions with serialized UID and 2D codes

For manufacturing workflows that require tracking, we implement serialized marking schemes and 2D data matrix codes readable by common industrial readers. Marks are placed following part-level considerations for readability and durability, and we can integrate with client inventory systems to associate mark data with production metadata. This supports warranty tracking, recall workflows and regulatory compliance where item-level identification is necessary.

Low-run flexibility and rapid prototyping

We handle single-piece proofs through small-to-medium production runs without large setup costs. Rapid sample service enables clients to approve mark placement, contrast and aesthetic before a full run. This agility suits designers, makers and small manufacturers who require professional marking without minimums typical of other processes.

Durability testing and adhesion validation

Marks undergo durability checks including abrasion, salt-spray and solvent exposure where relevant. We test marks in simulated service conditions to validate that they retain legibility and adhesion characteristics required by the application, reducing field failures and maintaining legible identifiers over product lifetime.

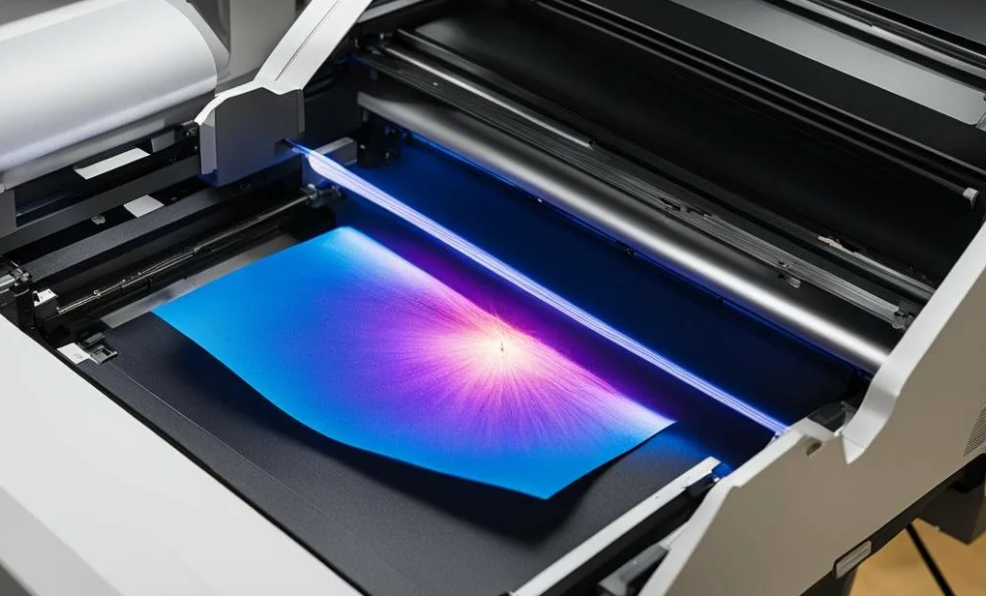

High-resolution decorative engraving options

Beyond functional marking we provide fine decorative engraving with photorealistic results on select materials. This capability supports premium product lines, commemorative pieces and custom gifts where surface detail quality is paramount and tactile finish is a brand asset.

Process control and batch documentation

Each production run is accompanied by a process record capturing machine settings, operator, artwork version and photographic verification. This documentation supports quality audits, offers traceability for downstream stakeholders and simplifies reorders with exact replication of previous outputs.