About Us — combining engineering, materials science and craft

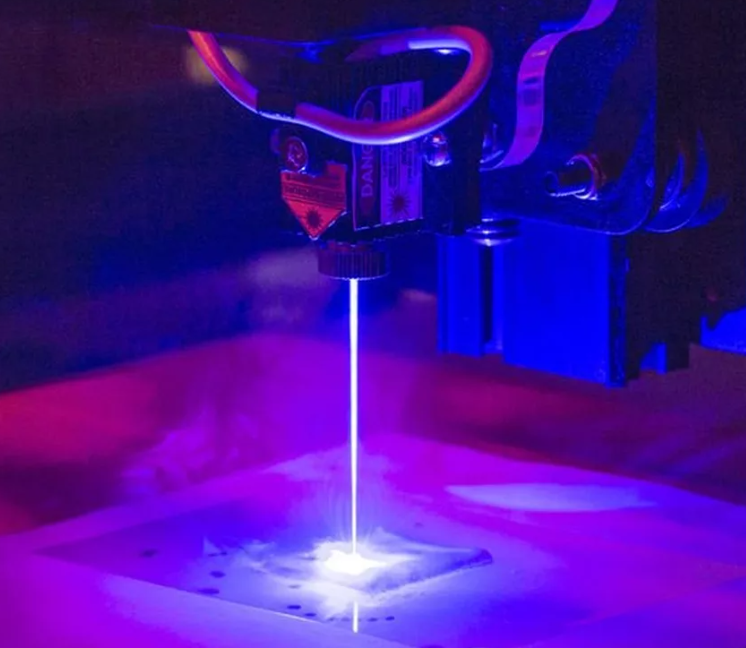

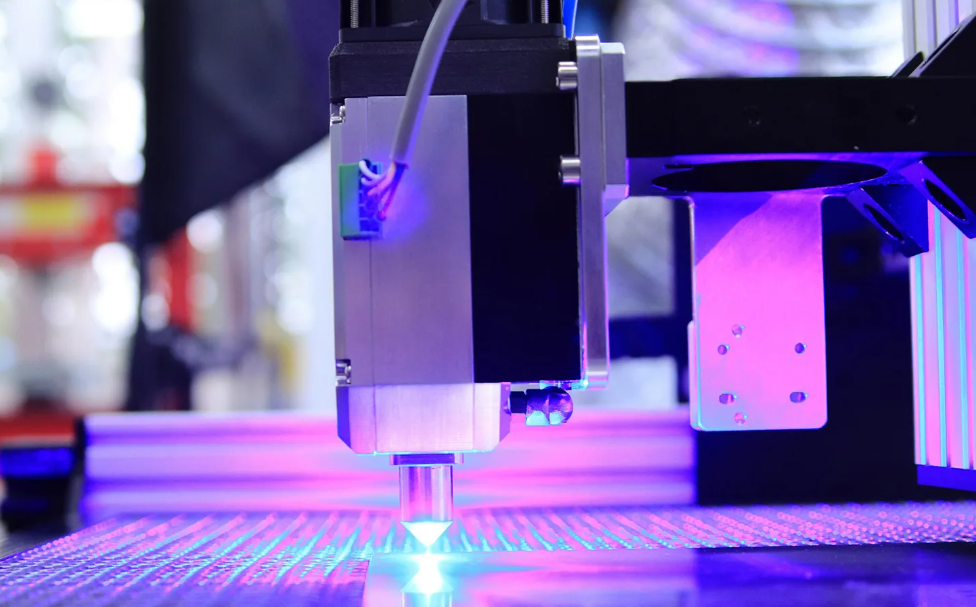

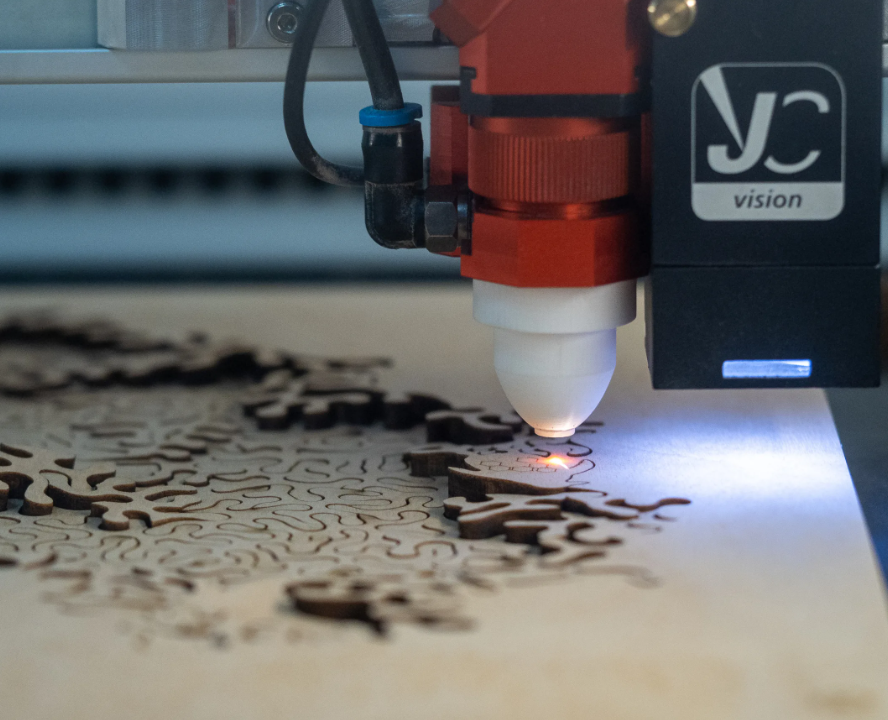

Our operation sits at the intersection of applied optics, materials knowledge and production discipline. Laser processes are not universal; understanding the interaction between beam characteristics and material microstructure is essential to achieve marks that are both aesthetically acceptable and technically durable. We maintain a library of tested parameters and past results that speeds onboarding of new materials and reduces experimental iterations. Our team includes technicians experienced with micron-scale positioning, artwork preparation specialists who optimize vector and raster data for laser workflows, and quality engineers who define acceptance criteria for contrast, readability and adhesion.

We work across diverse sectors: aerospace and industrial components that need permanent UID marks, medical device manufacturers requiring traceable identifiers, designer brands seeking high-fidelity engraving, and product developers testing small runs for market validation. Each sector brings different constraints—thermal sensitivity, surface coating considerations, or regulatory label permanence—and our process begins with a brief and sample validation to ensure the chosen marking approach satisfies those constraints.

Sustainability is considered in our operations: we recommend substrate combinations that withstand marking without the need for over-processing, and we manage waste responsibly. Where chemical post-treatments are required we use controlled handling and document disposal. For clients focused on long-term part life we provide guidance on mark placement to minimise exposure to wear and on sealing or coating strategies that enhance longevity when needed.

Our commitment is practical: reproducibility, clarity and a process that integrates with client manufacturing rhythms. For bespoke design requests we produce a visual proofing stage and engage with client teams to reconcile aesthetics and marking function, ensuring the final product satisfies both visual and operational expectations.